How Fracking Affects Gas Prices 1.0

How Fracking Affects Gas Prices 1.0

Cash 4 Cars Cleveland is back with our latest news and information update. Are you looking for a salvage car buyer or scrap vehicle buyer in order to get money for a junk car? There are many people that buy junk cars, but few make the process of obtaining money for a junk car as easy as we do. Our scrap vehicle buyer and other people that buy junk cars are awaiting your call 6 days a week throughout University Heights, Warrensville Heights, and Euclid. Residents of Macedonia, Bratenahl, and Mantua are encouraged to send the year, make and model of your vehicle to our scrap vehicle buyer. We have expanded the area that we offer scrap car hauling and unwanted vehicle removal service in to encompass the counties of Cuyahoga, Lake and Geauga.

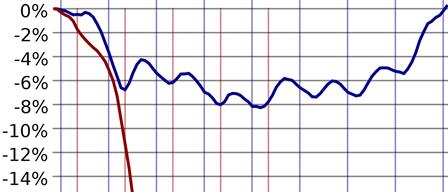

Those in the auto recycling world are obviously impacted significantly by fluctuations in commodity prices. Automobile fuel prices are among the most important, since we rely on it to operate many vehicles and types of equipment. Another indirect way that vehicle gas prices impact our business is that effect the market for aluminum; this occurs because low oil costs make plastic much less costly to produce, thus a more attractive option for several products that compete with aluminum. The goals of this two-part study include the following:

- Define the process and goals of fracking and examine the environmental concerns?

- Determining how much influence US fracking has had so far on oil prices.

- Learning about what will likely be the future within the US fracking market.

Understanding the Process

In a 2015 article titled ‘Is Fracking Safe? The 10 Most Controversial Claims about Natural Gas Drilling’ was posted on Popular Mechanics with the following data: “Natural gas trapped in deep buried rock is accessible by advances in two technologies: horizontal drilling, which allows vertical wells to turn & snake more than a mile sideways through the earth, and hydraulic fracturing (HF), or fracking. Developed over 60 years ago, fracking involves pumping millions of gallons of chemically treated water into deep shale at pressures of 9000psi+. This fluid cracks the shale or widens existing cracks, freeing hydrocarbons to flow toward the well. There have been large increases in shale gas production recently. The Energy Administration says shale gas will account for 50% of the natural gas produced in the U.S. by 2035. Controversy and disputes over fracking have grown heated in the vicinity of the Marcellus Shale. Terry Engelder, a professor at Penn State says the vast formation sprawling beneath WV, PA and NY could produce an estimated 493 trillion cubic feet of gas over its 50-100-year life span. That is enough to power every natural gas—burning device in the US for 20+years. The debate over the Marcellus Shale will shape national energy policy—including how fully, and at what cost, we exploit this vast resource. The link to the article is here.

Next we look at a contrast on how the process is defined by the EPA in their segment ‘The Process of Hydraulic Fracturing’ as follows: “HF produces fractures in the rock formation that stimulate the flow of natural gas or oil, increasing the volumes that can be recovered. Wells may be drilled vertically up to thousands of feet below the surface & horizontally extending thousands of feet. Fractures are created by pumping large quantities of fluids at high pressure into the target rock formation. HF fluid commonly consists of water, proppant and chemical additives that open and enlarge fractures within the rock. The proppants – sand, ceramic pellets or other small incompressible particles – hold open the newly created fractures.

Once the injection process is done, the internal pressure of the rock formation causes fluid to return to the surface through the wellbore. This fluid is known as both “flowback” and “produced water” and may contain the injected chemicals plus naturally occurring materials such as brines, metals, radionuclides, and hydrocarbons. The flowback is typically stored on-site in tanks or pits before treatment, disposal or recycling. In many cases, it is injected underground for disposal, or it may be treated and processed by a wastewater treatment facility and then discharged. HF is a technique used in “unconventional” gas production. “Unconventional” reservoirs can cost-effectively produce gas only by using a special stimulation technique, like HF, or other special processes. Extracting unconventional gas is relatively new; the main technologies, HF and horizontal drilling, have opened up new areas for oil & gas development, with a focus on natural gas reservoirs such as shale, coalbed and tight sands.

Shale Gas Extraction: Shale rock formations have become an important source of natural gas in the US. Present in many locations, some of them are where oil or gas production has never occurred before.

Production of Coalbed Methane: Coalbed methane was first extracted from coal mines as a safety measure to reduce the explosion hazards. Today the methane is captured and used as energy; deeper formations might require hydraulic fracturing to release the natural gas.

Tight Sands: Gas-bearing, fine-grained sandstones or carbonates. Unless natural fractures are present, most tight sand reservoirs require hydraulic fracturing to release gas.

The full article is available here.

Environmental Concerns

Citing the Popular Mechanics article above, we learned the following[1]: HF uses a lot of water; taking up to 7M gallons to frack a single well, and at least 30% of that water is lost. There is evidence that fracking has depleted water supplies in drought-stricken TX, but a study by Carnegie Mellon indicates the Marcellus region has plenty of water and an adequate system to regulate its usage. The amount of water required to drill all 2916 of the Marcellus wells permitted in PA in 2010 would equal the amount of drinking water used by Pittsburgh, during the same period, says environmental professor Jeanne VanBriesen. She notes that water withdrawals of this new industry are taking the place of water once used in steel manufacturing. Hydrogeologist David Yoxtheimer of PSU’s Marcellus Center for Outreach gives the withdrawals more context: Of the 9.5B gallons of water used daily in PA, natural gas development consumes 1.9M gallons a day (mgd); livestock use 62 mgd; mining, 96 mgd; and industry, 770 mgd.

Burning natural gas is cleaner than oil or gas, and it emits half as much carbon dioxide, less than 1/3 the nitrogen oxides, and 1% as much sulfur oxides as coal combustion. Not all shale gas makes it to the fuel tank or power plant. The methane that escapes when drilling is shipped via pipelines and is a greenhouse gas. Robert Howarth at Cornell University calculated that methane losses could be as high as 8%. Industry officials concede that they could be losing anywhere between 1-3%. Some of those leaks can be prevented by aggressively sealing condensers, pipelines & wellheads. But there’s another upstream factor to consider: Drilling is an energy-intensive business. It relies on diesel engines & generators to power rigs, and heavy trucks making hundreds of trips to drill sites before a well is completed. One solution to lower emissions is using natural gas itself to power the process.

Next we will also consider the EPA information regarding environmental concerns from the same source above[2]: “The EPA’s study of the potential impacts of hydraulic fracturing (HF) for oil and gas on drinking water resources, conducted retrospective case studies at five sites where HF had already occurred. They sought to identify whether an impact had occurred, and if so, to understand the causes. The case studies provide insights into vulnerabilities and ways for impacts to drinking water from these activities. The case studies highlight the value of site-specific background data, including the chemicals used on site, and local geological info. States cooperated with the EPA on these studies, and independently took follow-up steps to protect water resources at all locations.

Killdeer, ND: The drinking water wells sampled did not show the presence of chemicals or brine; however, two monitoring wells screened in the aquifer showed the presence of brine & tert-butyl alcohol (TBA, whose only potential source was the blowout during HF.

Northeastern PA: Background data showed methane as naturally occurring in the area; however, using multiple lines of evidence concluded that up 25% of the water wells are impacted by gas associated with HF activities.

Southwestern PA: Found increased levels of chloride in ground water near a site which contained HF wastewaters & drilling waste. The chloride contamination likely originates from the impoundment site based on multiple lines of evidence. The isotopic signature of methane in domestic wells wasn’t similar to that of gas from the shale being hydraulically fractured.

Wise County, TX: Two domestic wells were impacted; brines associated with the specific geological formation were the only source that was consistent with the observed impacts. Screening also identified a 3rd located at an industrial facility that was potentially impacted by brines and/or landfill leachate.

Raton Basin, CO: Dissolved methane is naturally present through-out the Raton Basin and EPA detected it in all samples collected from the wells. Some gas migration had occurred but can’t be definitively linked to HF.

Some drilling operators recycle wastewater to replace water fracturing fluid for re-use. This practice has the potential to reduce discharges to treatment facilities or surface waters, minimize underground injection of wastewater and conserve water resources. There have been documented air quality impacts in areas with natural gas development, with increases in emissions of methane, volatile organic compounds (VOCs) and others. Through the Natural Gas STAR program, EPA and partners identified technologies & practices that can reduce methane emissions. The EPA is promoting newer, efficient technology and cleaner fuels to innovate.

Stay tuned for our 2nd segment!

Cash 4 Cars Cleveland will pay money for a junk car in Pepper Pike, Aurora, or Shaker Heights. People that buy junk cars have an obligation to insure that the vehicle they recycle are handled in a manner which is safe for the environment. We are a salvage car buyer that strives to insure that during the scrap car hauling and junk car recycling processes, the proper precautions are taken. We have been a scrap vehicle buyer serving the regions of North Randall, Richmond Heights, and Solon, for several years and have an established protocol in place. Those looking to sell a scrap car for cash in Walton Hills, Streetsboro, and Mentor can all the areas “home of junk car scrapping” at (216) 359-1010. Our salvage car buyer is standing by to provide a junk car quote for those needing to know how to scrap old car in Sagamore Hills, Middleburg Heights, and Glenwillow. Even those with a broken down vehicle in areas like Twinsburg, Lakewood, or Linndale Village can take advantage of our cash for clunkers program.

[1] http://www.popularmechanics.com/science/energy/g161/top-10-myths-about-natural-gas-drilling-6386593/

[2] http://www.epa.gov/sites/production/files/2015-06/documents/final_retro_case_study_fact_sheet_6_03_508_km.pdf